IDAH CO., LTD.

Booth 3224

https://idah.com/

Sector: Feed / Feed Milling & Processing / CropTech-FeedTech

Idah Co., Ltd.

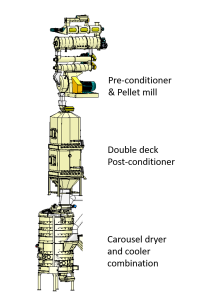

Do you know what is the latest technology in drying and cooling shrimp feed? IDAH considers all the requirements and the experience in the field and has developed a new generation of a pelleting system that incorporates the Carousel Dryer and Cooler Combination (TK-series) in one machine (Figure 1).

Figure 1. The third-generation (G3) shrimp feed pelleting system development offers total moisture control and saves drying energy.

IDAH sold the TK-series machine to China and India back in 2021. The two benefits of this system are:

- Total moisture control: easy and fast.

The TK-series can produce feed with ±0.5% moisture variance in both dryer and cooler. This combination solved the high moisture variance problem that usually occurs when applying the conventional box cooler. This TK-series machine lessens the point to control the production flow.

- Saving drying energy.

In a carousel dryer, the counter-flow drying airflow will support efficient heat transfer and give a low exhaust air temperature. The system utilizes the air exhaust from the cooler as makeup air for the dryer. The dust-free makeup air discharged from the cyclone (or jet filter) still contains some amount of heat and can lower energy use (15-30%) and reduce the amount of air emission (30-50%) and decrease odor problems.

Figure 2. The ±0.5% moisture variance in the carousel dryer-cooler lowers the amount of production flow control point in the shrimp feed pelleting production line.

For more information, please contact us at IDAH